The world of robotics is buzzing with excitement as companies strive to crack the code of developing highly functional robotic hands. These impressive creations are not merely for show; they represent the cutting edge of technology, aimed at enhancing the interaction between machines and the human environment. With the need for a versatile, efficient, and affordable robotic hand more pressing than ever, innovators are pushing the boundaries of what’s possible.

A Glimpse into the Past and Present

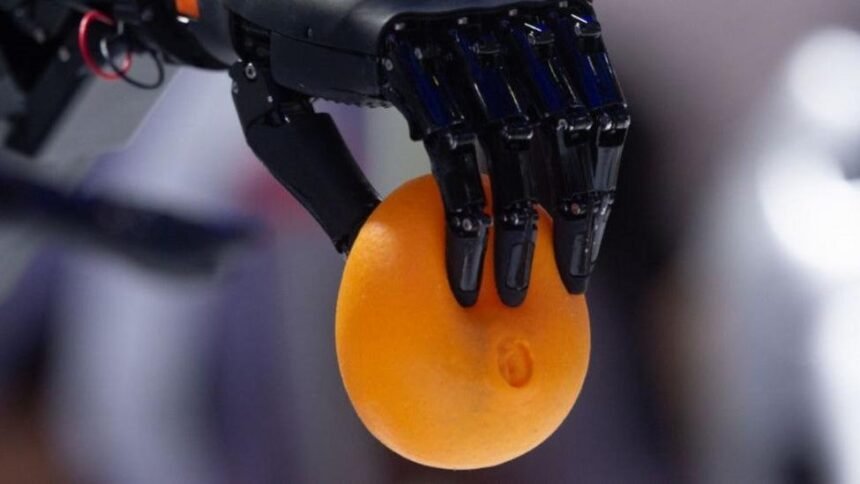

At the heart of this robotic revolution is Rich Walker, director of Shadow Robot, who fondly recalls the company’s humble beginnings in the late 1990s. Their first robotic hand, crafted from everyday materials like wood and rubber bands, laid the groundwork for the advanced technology we see today. Now, in Shadow Robot’s north London headquarters, the latest models feature cylindrical forearms housing small electric actuators, which manipulate metal tendons to move fingers with remarkable precision.

In a hands-on demonstration, I strapped sensors to my fingers to control the robotic hands. Contrary to my expectations of chaotic flailing, the movements were fluid and controlled, allowing me to effortlessly manipulate blocks and cups. With around 200 of these advanced hands already deployed, primarily in research and tech settings, Walker describes them as development kits for dexterity. “You get this hardware, explore its capabilities, and then you can determine what you want to build if you’re going to create a larger system,” he explains.

The Quest for a Universal Robotic Hand

The quest for a single, adaptable robotic hand that can perform a variety of tasks is a shared dream among many in the industry. Bren Pierce, founder of Bristol-based start-up Kinisi, notes that the human hand is the most complex feature of any humanoid robot. Kinisi is currently testing ten of its KR1 robots, which can be fitted with various grippers to suit different tasks, from heavy lifting with strong pincers to delicate handling using suction devices.

However, Pierce acknowledges the challenge of creating a hand versatile enough to manage all tasks. “Everyone has been dreaming for 40 years of one robot hand to rule the world,” he says. Although Kinisi has developed a three-fingered prototype, the real hurdles lie in durability, scalability, and affordability. With production costs of around £4,000 ($5,400) for their prototype, the price tag is significantly higher than the £400 cost of their simpler pincer models.

The Challenges of Dexterity and Affordability

This quest for innovation is underscored by comments from Elon Musk, who identified the creation of a dexterous robotic hand as one of the three major challenges in humanoid robotics. The other two hurdles involve developing advanced artificial intelligence and mass-producing these robots. As attention turns to Tesla’s upcoming humanoid robot, Optimus, expectations are high for its promised human-like dexterity.

Yet, experts like Nathan Lepora, a professor of Robotics and AI at Bristol University, remain sceptical about achieving human-level dexterity in the near future. He suggests that while advancements are being made, true robot hands that can match human skills may still be a decade away. As part of a UK government-funded project, Lepora is working on tendon-driven hands, predicting that sophisticated mechanisms will ultimately lead to more capable and affordable options.

Emerging Competitors in the Robotic Hand Market

While Western companies grapple with these challenges, firms in China are making significant strides. Wuji Technology from Shanghai is developing robotic hands featuring four independently controlled joints per finger, enabling intricate movements. Co-founder Yunzhe Pan highlights their hand’s durability and potential for future affordability. Priced at $12,000 (£8,800), Wuji aims to lower costs while enhancing functionality, incorporating piezoelectric sensors that provide a sense of touch—an essential breakthrough for humanoid robots.

However, the road to success is fraught with challenges. Pierce points out that while many research labs develop impressive sensors, they often have limited operational lifespans. “In industry, I want this robot to work for 10 years,” he insists. Encouragingly, experts like Lepora believe that substantial investments in humanoid robotics are driving meaningful progress.

Why it Matters

The pursuit of advanced robotic hands is not just a technological challenge; it holds the potential to transform industries, enhance human productivity, and redefine our interaction with machines. As researchers and companies worldwide strive to create hands that can imitate human dexterity, we stand on the brink of a revolution that could change the way we work, play, and live alongside intelligent machines. The future of robotics is undoubtedly bright, and the progress being made today will pave the way for a more integrated tomorrow.